dhf has compiled the most pertinent reasons as to why automated gates can cause injury or death, as well as how to prevent this. ‘The 7 deadly sins of automated gates’, authored by dhf ’s Senior Training & Compliance Officer, Nick Perkins, aims to create greater awareness and to educate the public and the industry on the dangers of poor installation and maintenance, as well as how to spot an unsafe gate.

Central to safety and legal compliance is the European gate safety standard, EN 12453, first published in 2000. Under this standard, the following deadly sins should not occur and are not permitted.

The first deadly sin is defective sliding gate travel stops.

As Nick explains: “Sliding gates coming out of their runners and falling on a person is by far the most common cause of automated gate death, injury, and prosecution. This should never happen.

It is a requirement of machinery safety law that both normal use and foreseeable misuse must be catered for. Most incidents of this nature occur when the gate is being moved manually, often as a result of power failure. A motorist who is being delayed by a failed gate may well exert considerable force to move it, so travel stops need to be very substantial and resilient enough to cope. The gate should be constructed so that derailment and falling over are prevented.”

It is a requirement of machinery safety law that both normal use and foreseeable misuse must be catered for. Most incidents of this nature occur when the gate is being moved manually, often as a result of power failure. A motorist who is being delayed by a failed gate may well exert considerable force to move it, so travel stops need to be very substantial and resilient enough to cope. The gate should be constructed so that derailment and falling over are prevented.”

For further information, see section 2.1.2 of DHF TS 013-1:2021 Part 1: On-site guide.

Nick cites the second deadly sin to be hinge failure. The gate must be constructed to prevent falling over in the case of a failed suspension component; several deaths and injuries have been caused in this way.

Nick explains that: “In 2017, these rules were relaxed to allow the use of a safety lanyard. Today, a limited amount of movement from vertical is permitted (up to 300mm) if a hinge fails. Possible solutions include triple hinge, dual hinge and lanyard, or super reinforced hinges that can prevent falling over by themselves if one of them fails.”

For further information, see section 2.1.3 & 2.1.4 of DHF TS 013-1:2021 Part 1: On-site guide.

Draw-in at sliding gates is number three.

This is the hazard that occurs where a sliding gate passes a fixed object such as its support frame, wall, or other fixed object. Again, serious injuries have been caused in this way. “It should not be possible for a person to be drawn in by a moving gate”, says Nick.

“Where a sliding gate is constructed with open bars rather than being full-filled or boarded over, any draw-in hazard will also be accompanied by a shearing (guillotine) hazard between the uprights in the gate and nearby fixed structures.” These hazards must be prevented by enclosure fence or screen in the run-back area, provision of safe edges close to the moving gate surface, or by the provision of full height optical safety devices such as light curtains or laser scanners. For further information, see section 4.5 of DHF TS 013-1:2021 Part 1: On-site guide.

Reducing hinge gaps is Nick’s fourth deadly sin.

Injuries, deaths, and prosecutions have resulted from reducing gaps at the hinges of automated gates.

Nick explains: “Reducing hinge gaps must be prevented by safe design (avoidance of reducing gaps), flexible guards, safe edges, or optical safety devices.” For further information, see section 4.4 of DHF TS 013-1:2021 Part 1: On-site guide.

Excessive closing force is sin number five.

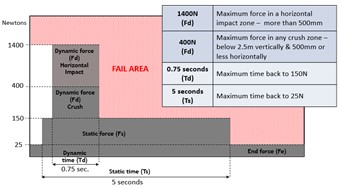

“EN 12453 provides three main methods for protecting the main closing edge of a powered gate: hold-to-run, force limitation or non-contact presence detection.

“Force limitation is the most commonly used method; it limits the amount of force that can exerted on a person to safer limits,” Nick continues. “In horizontally reducing gaps of 500mm or less, and all vertically reducing gaps below 2.5m, the maximum permitted force is 400N (40kg dead weight), whilst in horizontally reducing gaps greater than 500mm, it is 1400N (140kg dead weight). Below 500mm, a person can be crushed between the moving gate and something else, whilst in larger open spaces a person can be pushed along but is free to escape. In all cases, force must be back down to 150N (15kg) within three-quarters of a second and 25N (2.5kg) within five seconds; almost invariably, the gate or barrier will need to reverse to achieve this. Both force and reversal time must be accurately controlled to achieve safety and compliance.”

Force limitation can be achieved by safe edges (rubber contact strips) that work by sending a signal to the control unit when they touch a person, or inherent force limitation provided by a sensitive drive unit.

“Used correctly and appropriately, both are perfectly viable methods of providing the required safety, providing they are tested accurately and maintained in a safe condition”, says Nick. Force limitation must be tested using an annually calibrated force test meter that conforms to EN 12453 to ensure both force and reduction time are accurately measured to accurately verify that safety and compliance are achieved. Nick goes on to explain: “It is not possible to test all the areas of a gate system that rely on limited force for safety; some areas must be verified by analysis of the readings taken at the main edge”.

DHF TS 013 on-site guide explains how to do this in sections 6.5.3 & 6.5.4.

EN 12453 requires that, where automatic gates are protected by force limitation, they must also be equipped with ‘supplementary’ beams to reduce the probability that a person will be contacted by a force limited gate. Nick explains that: “Although the beams are a mandatory requirement to limit the probability of contact, the primary requirement is to limit force wherever contact with a person is possible. Supplementary beams cannot provide the degree of safety necessary for primary safety; it is too easy to inadvertently avoid them in normal use.”

Nick’s sixth deadly sin is excessive crushing force at hinged gate lower edges.

A lot of focus is rightly placed on main closing edge safety, but this is the area where a hinged gate exerts the least force when closing.

“The much wider swept arc described by the lower edges during opening and closing will exert much higher force”, explains Nick. “The gate will generate dramatically increasing levels of force along the lower edges towards the hinge; body parts can more easily be injured in these areas as the gate opens or closes.

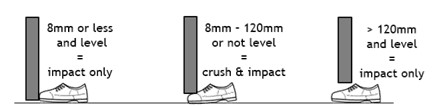

“The limits on acceptable force are straightforward”, explains Nick. “Where body parts can be crushed, it is 400N or, where there is no crush potential, but a person may be impacted, it is 1400N. According to EN 12453, areas where a body part could be crushed, must be assessed against the safety distances specified in the machine guarding standard EN 349.” Nick continues: “Feet and ankles are at greatest risk but the effect of the moving gate on hands, arms and other body parts of a fallen person must also be protected. Where there is a constant gap of up to 8mm or 120mm or more, the hazard is also impact only, but where the gap is between 8mm and 120mm, or where the gap changes due to slopes or kerbs etc during movement, there is a crush potential. For the vast majority of gates, there is a crush hazard along the lower edges and hence the maximum allowable force is usually 400N.

“Safe edges are ideal for protection because they rely on the overtravel of the gate (stopping distance) being less that the compression available in the safe edge to achieve safe results. As hinged gate overtravel reduces towards the hinge, any safe edge that can produce a safe force at the main closing edge end will also provide safe force at the hinge end. Inherent force limitation provided by sensitive drive units has the inverse effect, however; it is very sensitive at the main edge end of a hinged gate, but sensitivity reduces dramatically towards the hinge end. So, if there are crush hazards under the gate towards the hinge end, safe edges will be required on the lower edges to achieve the required safe force in these hazard areas.”

For further information, see section 4.3 of DHF TS 013-1:2021 Part 1: On-site guide.

The final deadly sin is uncontrolled closing force on traffic barriers.

As traffic barriers are covered by EN 12453, exactly the same safety rules apply. Despite rising arm barriers being primarily intended to control traffic, the previously mentioned machinery safety law requirement to cater for normal use and foreseeable misuse, traffic barriers must also be safe for people. Nick explains: “Too many traffic barriers do not have the required protection on their closing edges. Many rely on magnetic vehicle detectors (useless for people) or rely solely on beams intended to supplement force limitation (see sin # 5) but without the required force limitation.”

For further information, see section 6 of DHF TS 013-1:2021 Part 1: On-site guide.

Nick concludes: “As a federation, DHF is totally committed to raising standards, educating the public and increasing awareness across the industry. There really is no place in our sector for illegal products and unsafe installations. Thankfully, the message is continuing to get out there as a result of our comprehensive training programmes, technical specifications, and collaborative working.”

Join dhf

Enjoy the full benefits of dhf membership

Apply today